No products in the BAG.

GRINDING HEAD LUBRICATION PROCEDURE

**Only Non-Toxic USDA Approved Synthetic Grease Should Be Used**

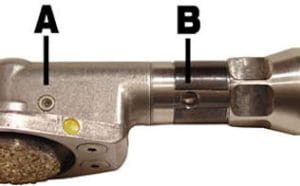

The PowerFloat® has two grease fill ports. One located on the end of the grinding head (Fig.1 A); and the other located further along the shaft, situated beside the collar (Fig.2 D). USDA approved synthetic grease is required for smooth operation.

Grease should be applied at the end of the day prior to putting equipment away.

- To grease, rotate the shaft locking cover (Fig.2 C), until the shaft hole is uncovered (Fig.1 B).

- The grease gun performs similar to a plunger. Insert the tip into the grease port and push down on the grease gun (don’t use excessive force) to force grease into the grease port (Fig.3).

- Apply grease until a small amount of new grease (i.e. clean) is seen coming out of the shaft locking hole (Fig.3 E).

- Two to four full pumps of grease into Grease Port (A) should be sufficient. The rule is to pump grease into Grease Port (A) until clean grease circulates through and exits from the shaft opening. The Grease Port usually requires two pumps from the grease plunger. Synthetic grease (USDA approved) can usually be purchased at local automotive retail stores.

CAUTION:

Do not apply grease into grease port unless the port opening is clean enough to see the silver check valve ball. Before applying the grease to the grease port, clean any debris from the opening. Do not insert a hypodermic needle or sharp object into the opening to clean debris. Only clean opening with with a wet, stiff bristled, nylon brush. Beneath the opening lies a small spring-loaded ball. Excessive pressure with any instrument may damage the mechanism. After physical removal of tooth debris from the port area, more cleaning may be done by spraying the area with WD-40™. Always lubricate grinding head before storing. Greasing before storage will aid in the prevention of corrosion of the internal gears and bearings.

Inability to grease means that the grease fitting ball (grease port) has seized. Contact PowerFloat to obtain a new fitting (grease port) with instructions for replacement.

**Only Non-Toxic USDA Approved Synthetic Grease Should Be Used**